PROTOTYPING.

RAPID MANUFACTURING.

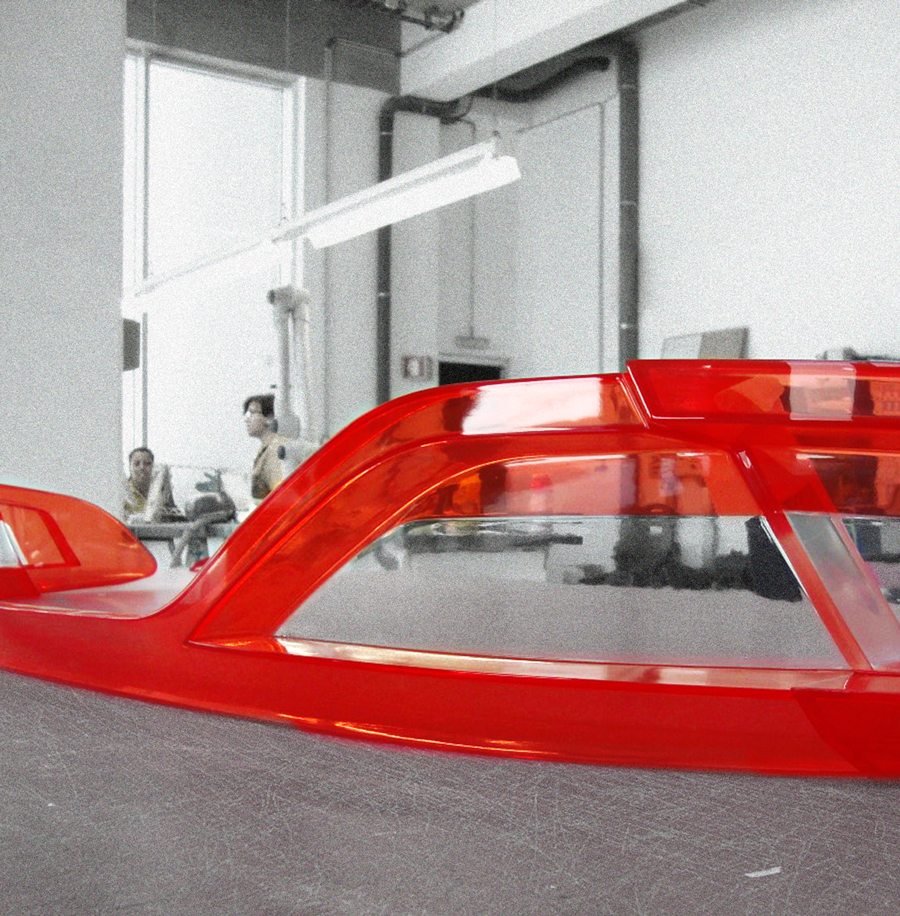

We understand the importance of quick turnaround times. Our advanced silicone moulds and 3D printing capabilities allow us to rapidly produce and deliver high-quality prototypes, serving as mockups of the design or functional models for product validation.

We can handle low volume production of real end-use parts that are suitable for applications requiring frequent design updates or low investment requirements.

Our commitment to efficiency and quality ensures that we meet the client’s manufacturing needs on time, every time.

PROTOTYPING

Why use prototyping?

Prototyping allows for thorough testing and validation of product design, ensuring aesthetics, ergonomics and functionality are on point. This efficient process identifies improvement needs promptly and correct them in short loops. As a consequence, it significantly reduces costs compared to making changes during mass production.

In short: Greater quality with smaller investment & much faster to market!

PROTOTYPING

From 1 parts

to small series

We have the ability to produce prototypes in different materials with diverse type of finishes. Mockup, validation or functional prototypes!

PROTOTYPING

Delivery from

2 days

Depending on the type of project or the production technology to be used, we can deliver parts in 2 days. We evaluate the context and needs to choose the best solution.

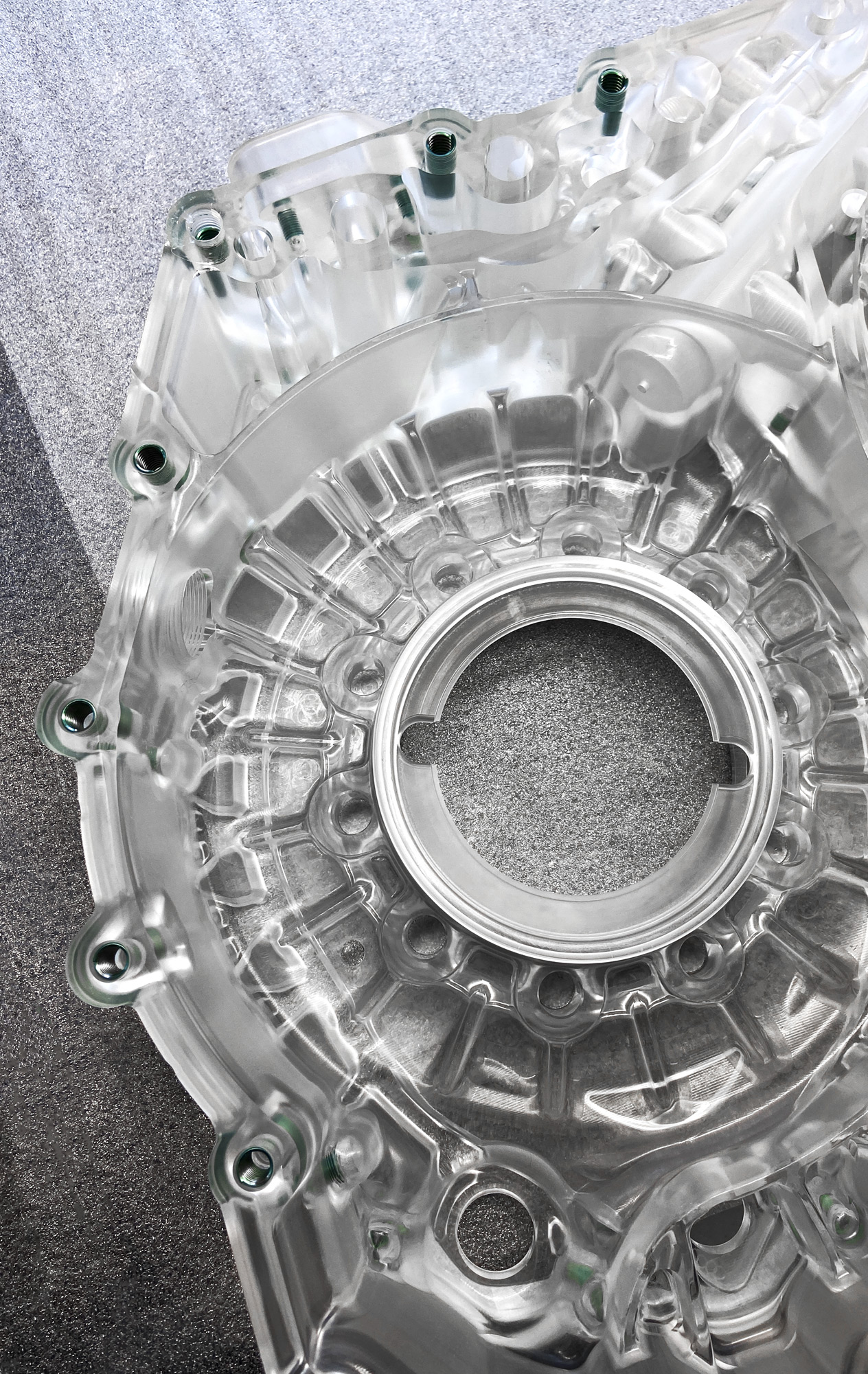

Finishing & Materials

We are able to produce different materials and textures like transparent or textured polymers, rigid or semi-rigid parts and elastomers.

SMALL SERIES

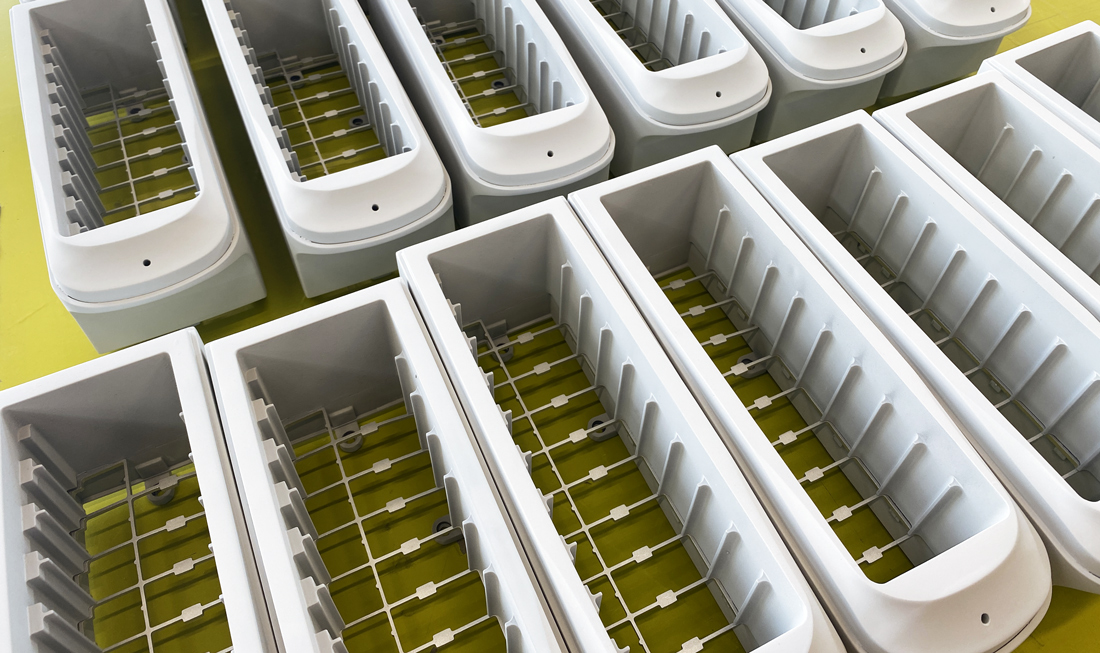

During the product development process, a small production volume is vital to ensure design and functionality. This is a cost-effective step to avoid problems in the future and to check all aspects of the final product.

Low volume manufacturing can also be the right choice for applications where large-scale quantity is not needed. So, this is a solution that will ensure fast delivery and an advantageous cost-benefit ratio.

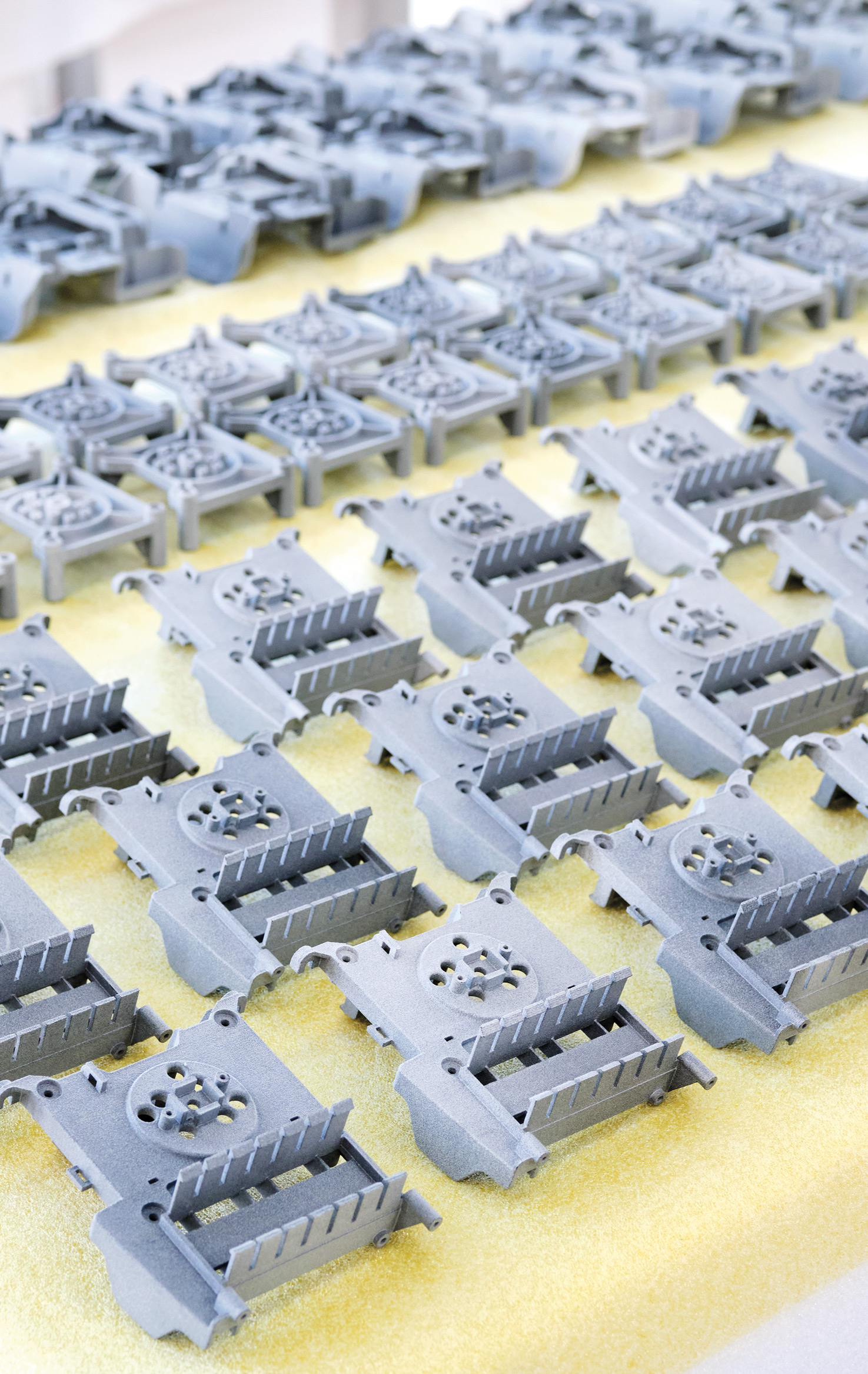

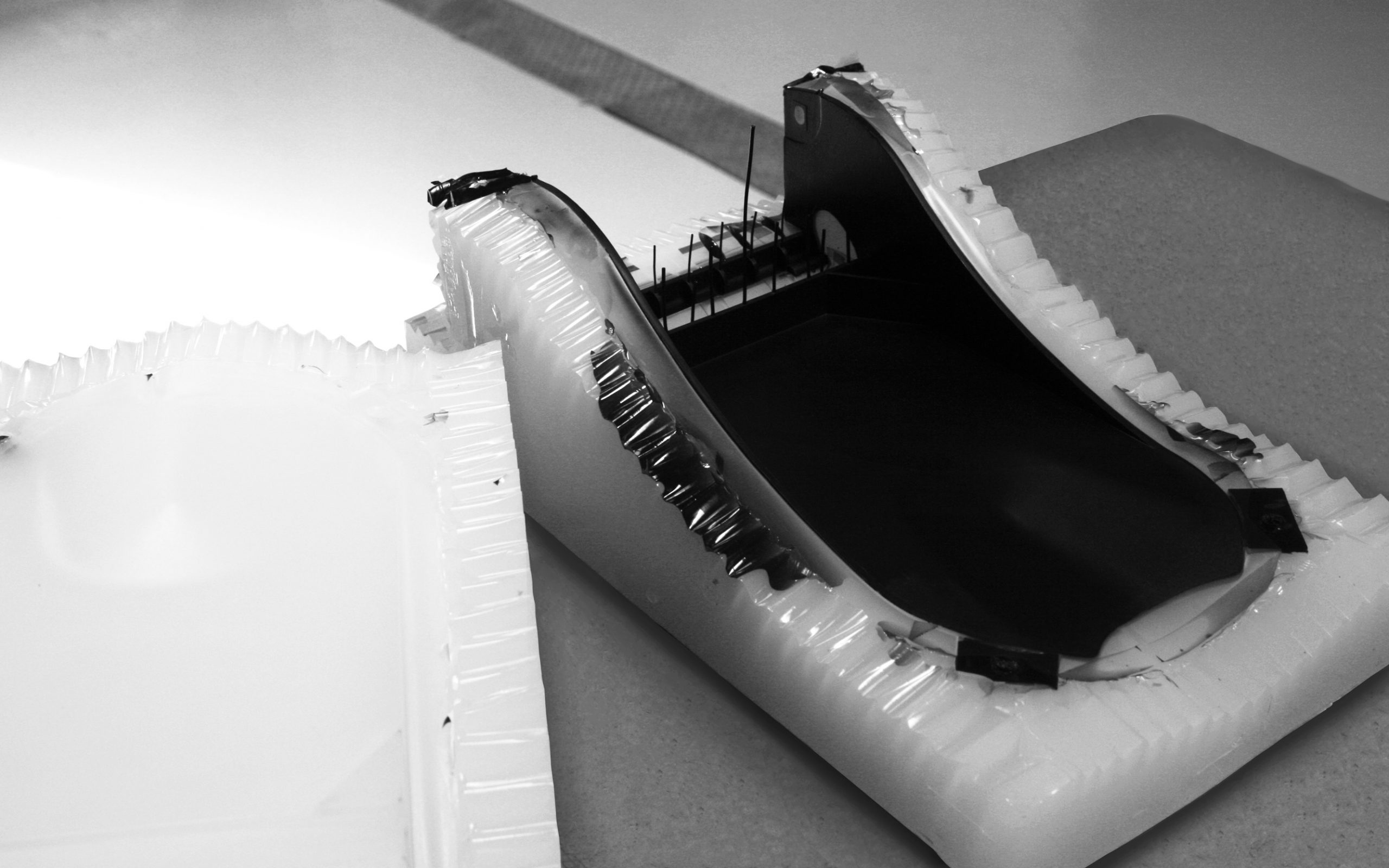

Vacuum casting allows to produce compound parts through silicon moulds without the complex engineering usually required by serial tools.

SMALL SERIES

Vacuum Casting

With silicone moulds technology, we can produce a small serie up to 100 units of one part in 3 weeks, improving time-to-market for our client’s products.

SMALL SERIES

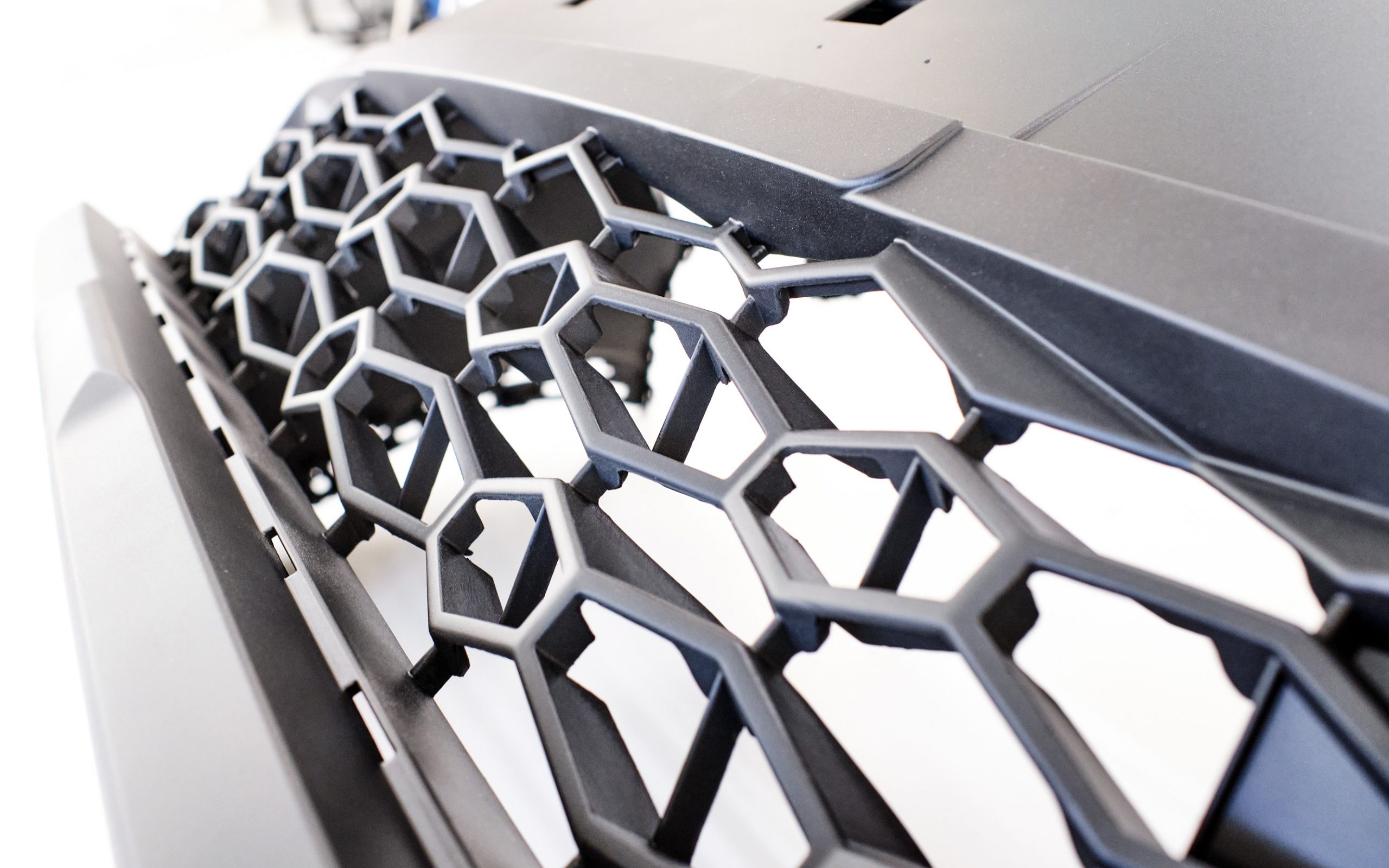

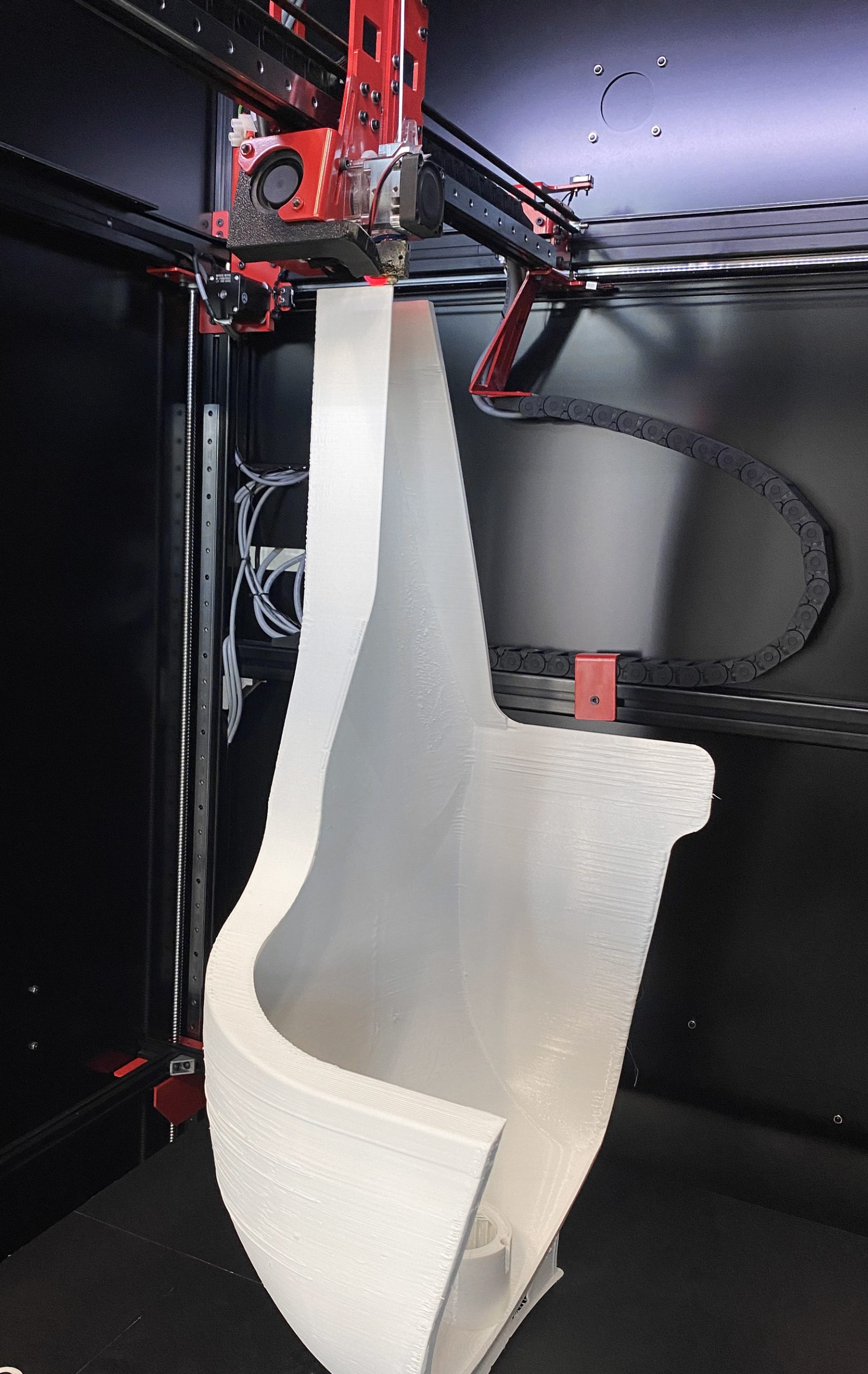

Large Parts

We are specialists in Rapid Manufacturing of large functional parts in polymers, suitable for real use. We can make single or multiple units for automotive industry, railway, consumer goods or agriculture.

SMALL SERIES

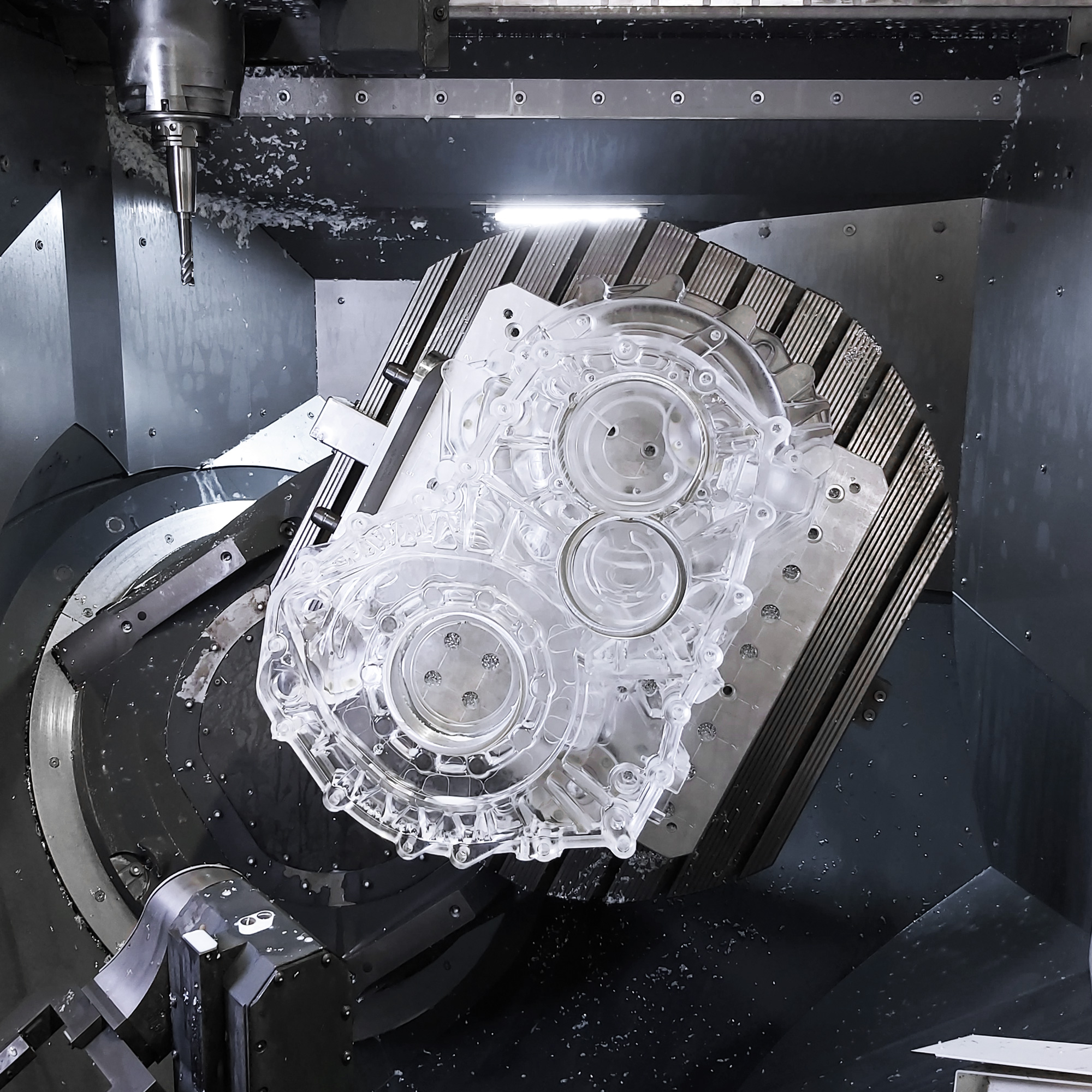

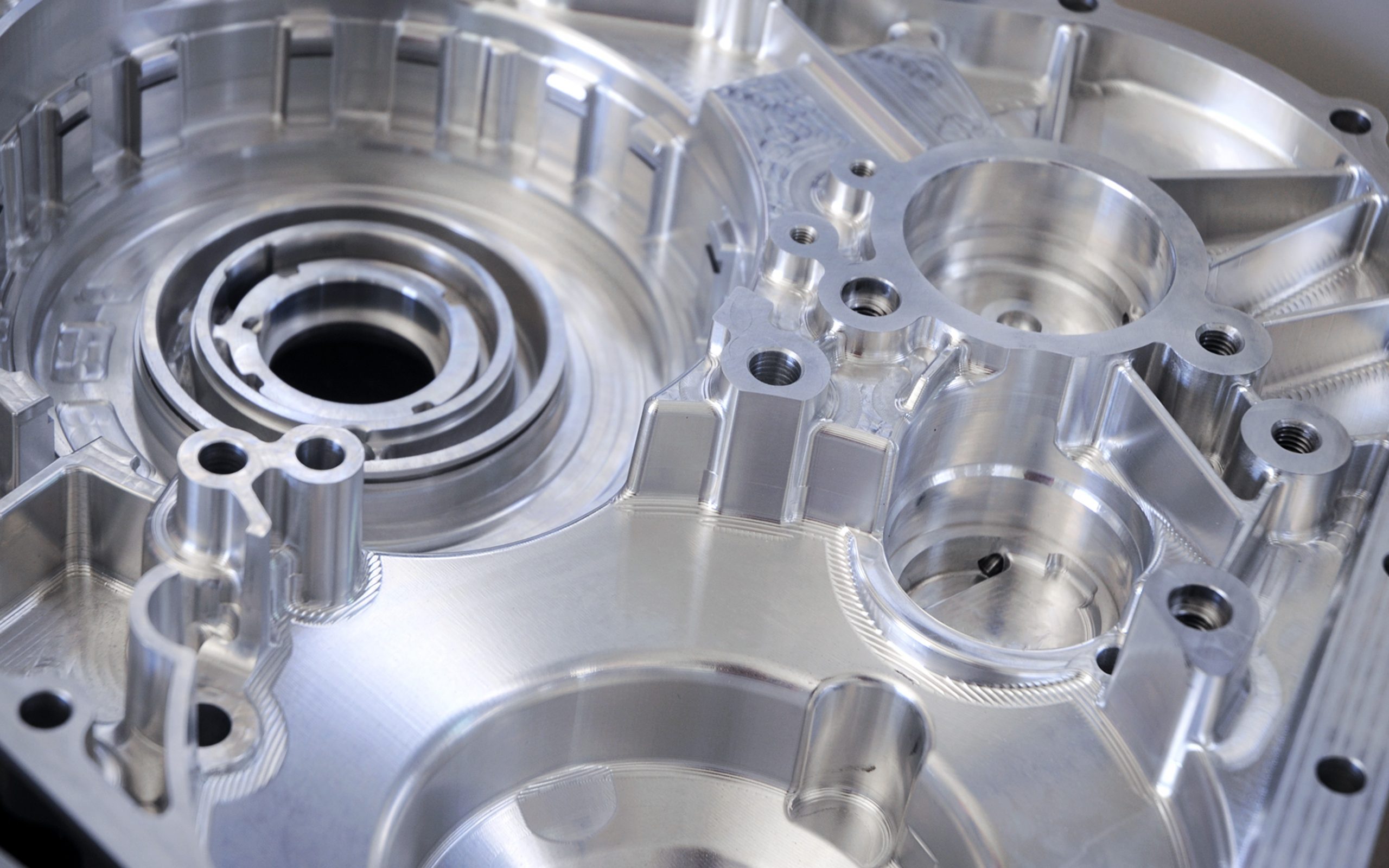

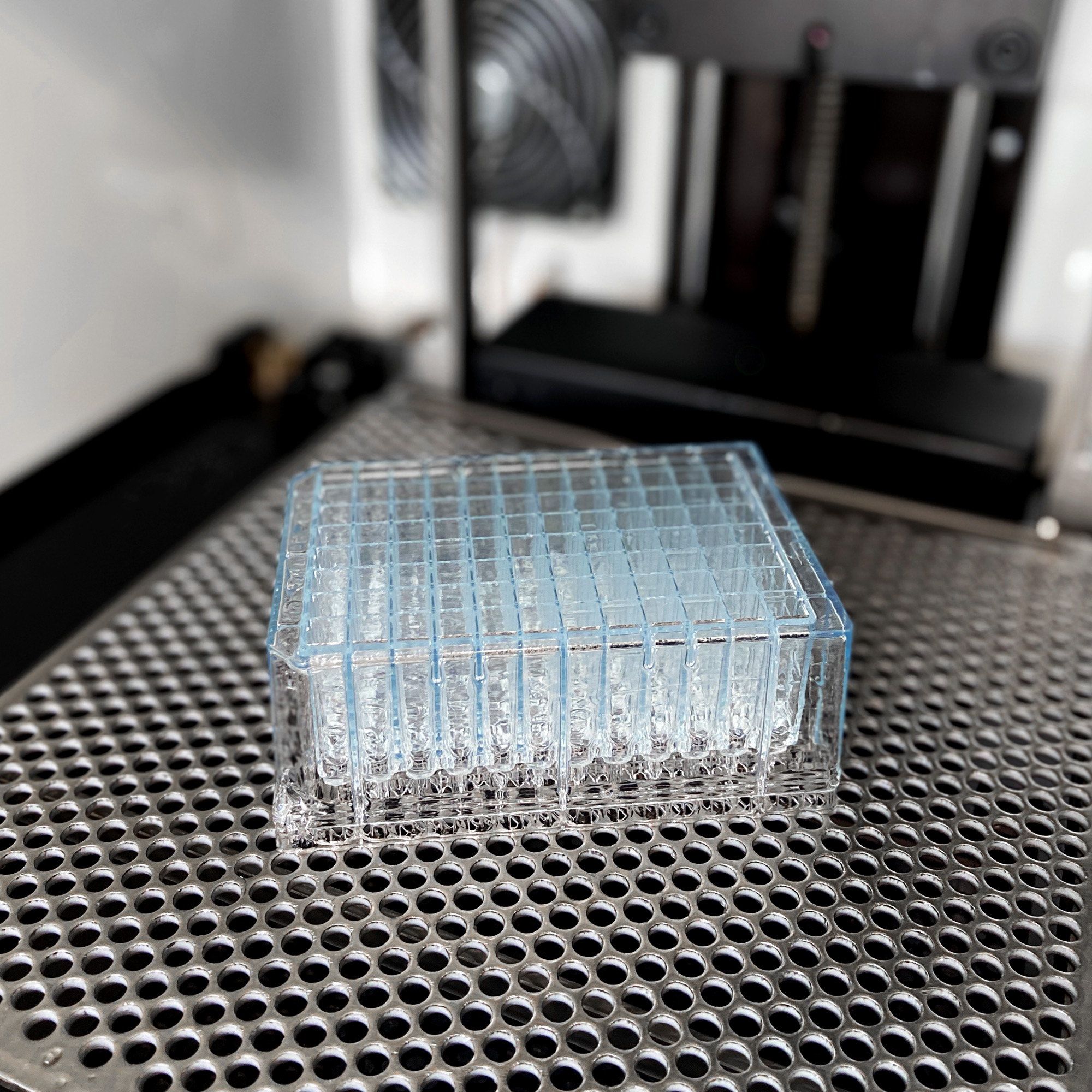

High Precision Milling Parts

In our High Precision Machining Centre, we have the capacity to produce complex parts, in materials like steel, aluminum or PMMA.